Patented FlushCut™ consumables have been specifically designed to allow Powermax users to cut attachments, lugs, pad eyes and other positive features as close to the base as possible without piercing or damaging the workpiece. An angled nozzle bore design and flat guiding shield enables flush cutting that leaves less than 5 mm (3/16”) residual material on the base or work piece, reducing grinding and secondary repair operations.

Typical flush cutting applications include:

- Removing lugs, pad eyes and temporary weld supports

- Material washing

- End cap removal

- Rat hole cuts in I and H beams

- Bolt and rivet washing

- Casting sprue removal

- Post tension cable tail cuts

- Wearable part removal/replacement

Flush cutting with plasma vs. oxyfuel

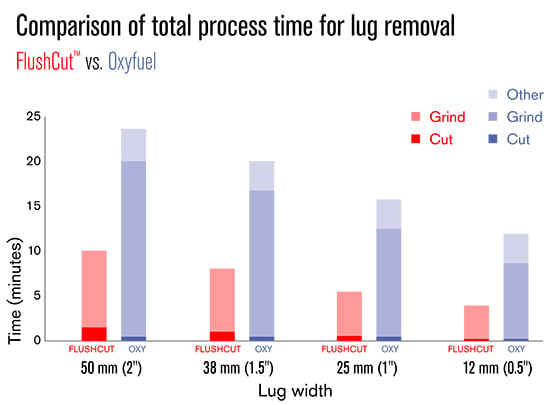

Plasma requires less overall pre-processing time than oxyfuel – no gas setting, purging or preheating – increasing the efficiency of the operation. And, unlike oxyfuel, plasma can be used to remove stainless steel attachments.

In addition, cutting with a Powermax® system significantly reduces the heat affected zone (HAZ)—about 10X less than when using oxyfuel. This is especially useful in flush cutting applications, and provides a number of important advantages:

- The ability to safely cut closer to the base material minimizes the need for secondary grinding

- Cutting closer to the base takes less material from the attachment, increasing the potential use, and reuse, of the attachments

* Based on lab results

See it in Action here:

Flush cutting with plasma vs. carbon arc gouging

With carbon arc gouging, the weld on both sides needs to be removed, requiring multiple passes and additional time on the job. The Powermax flush cutting process allows operators to remove lugs and attachments in a single cutting pass.

Flush cutting with plasma is also a quieter and less smoky process, which can improve the overall industrial hygiene of any shop or yard.

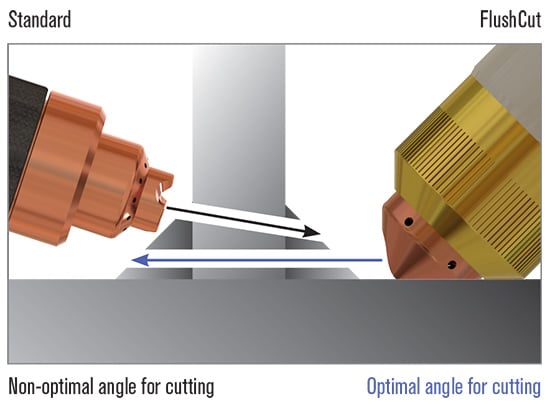

Flush cutting with plasma vs. traditional plasma cutting

The patented geometry of FlushCut™ consumables places the plasma arc in the ideal location for flush removals when compared to the arc delivery of a standard plasma cutting process. The optimized arc delivery with FlushCut consumables results in less post secondary grinding and material repairs.

FlushCut consumables can be used in both mechanized and handheld applications on the following Powermax torches and systems:

| System | Recommended amperage | Torch series |

| Powermax125® | 125 A | Duramax® Hyamp™ |

| Powermax105® | 105 A | Duramax® |

| Powermax85® | 45 A | Duramax® |

| Powermax65® | 45 A | Duramax® |

| Powermax45® XP | 45 A | Duramax® |

For more information on the benefits of these systems speak with one of our team 01603 605293

https://www.miganglia.co.uk/duramax-flushcut-starter-kit-65-105-a-1-complete-flushcut-stack-up.html